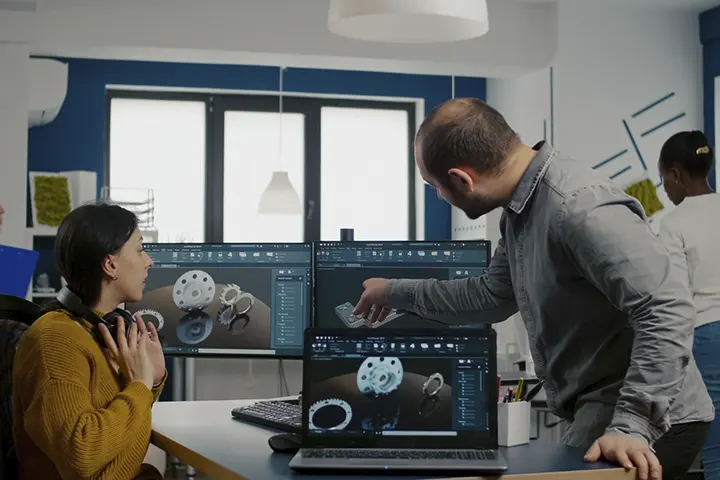

Using simulation software to design and test mechanical spare parts is a popular practice in the manufacturing industry. Simulation software allows engineers to create a 3D model of a part and test its functionality under various conditions before actually producing the part. This reduces the time and cost of designing and developing new products.

One of the benefits of using simulation software is the ability to check the strength and durability of parts. Engineers can use software to simulate the loading and stress that a part will experience under real-world use. This helps identify weak points and improve the design to make it stronger and more durable. This simulation also reduces the risk of part failure during actual use.

Simulation software can also be used to test a part’s performance under different operating conditions, such as temperature, pressure, and speed. These tests help engineers improve designs to suit actual operating conditions. and increase the efficiency of the work of the parts

The use of simulation software also helps in improving the production process. Engineers can simulate manufacturing processes to identify potential problems and make the process more efficient. The software can also be used to analyze material flow and heat distribution during the manufacturing process. This ensures that the parts produced are of high quality and without defects.

Simulation software is also useful in reducing the time it takes to develop new products by simulating and testing them in the design phase. Engineers can identify and fix problems before they enter production. This reduces product development time and reduces the cost of experimentation and model improvement.

However, using simulation software still has some challenges, such as creating a model that is accurate and consistent with actual operating conditions. and using data from simulation to improve designs and manufacturing processes. There must also be training and development of employees’ skills in using the software effectively.

In the future, the use of simulation software will play an increasingly important role in the design and testing of mechanical spare parts. With technology developing rapidly Simulation software is able to create highly accurate models and can test more complex operating conditions. Helps increase efficiency and reduce risk in designing and developing new products in the manufacturing industry.